Optimize industrial processes

The gigafactories of batteries requires toxic solvents, which require special expertise. In this context, EQUANS, a partner in the construction of European gigafactories, can design and build NMP decanting, storage and distribution facilities, and has developed a new NMP recovery and treatment process with a twofold objective: to optimize the site's energy consumption and to reduce its environmental impact in the long term.

Your issues

Our answer: NMP recovery

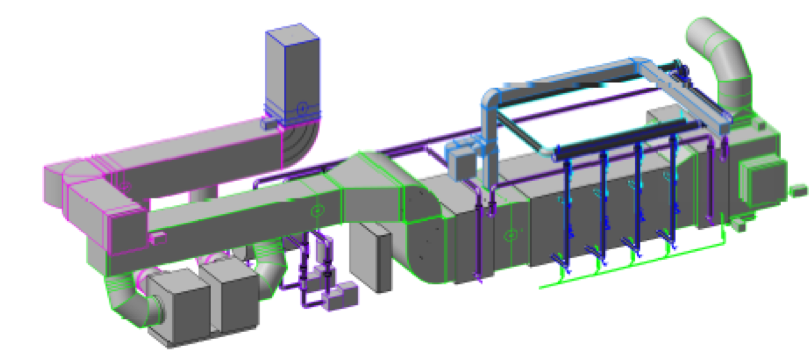

The manufacture of electric batteries requires the handling of explosive and highly flammable products. N-methyl-2-pyrrolidone (NMP) is used as an organic solvent in the production of lithium-ion battery cathodes. Concretely the production of the cathode consists of:

1- Coating the electrode with a solution of active materials approved by the solvent NMP.

2- Dry the film continuously in an oven at a temperature between 100 and 130°C, under controlled conditions to avoid any risk of explosion due to the evaporation of the solvent.

During this delicate operation, the NMP will turn into a gaseous state and evaporate into the oven drying air; At this point, it is imperative to remove it from the oven for two reasons:

1- For safety, because a too high concentration of NMP can be the cause of a risk of explosion.

2- For efficiency, because the drying operation requires controlled physico-chemical conditions.

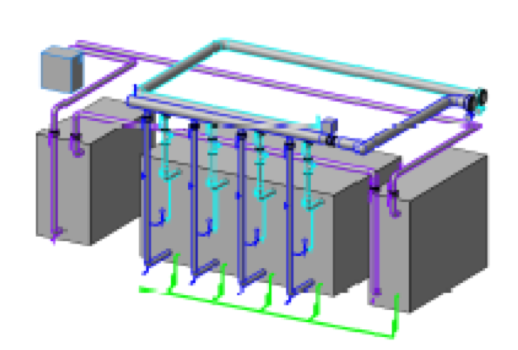

With this in mind, EQUANS has developed a virtuous system to extract the exhaust gas from the furnace and recover the NMP for reuse. EQUANS' expertise lies in its ability to design, build and install an NMP recovery process customized to the customer's facility, based on an innovative and protected condensation design.

- An innovative design to optimize the energy consumption of battery production unitsEquans' NMP condensation recovery process also provides optimal heat recovery, eliminating the need for thermal energy and reducing energy consumption by up to a factor of 15 compared to zeolite technologies!

- Limiting the environmental impactTo ensure the safety of people in the production areas, the rules impose to maintain the furnace in depression by a continuous extraction flow. Before being released into the environment, the extracted air undergoes a treatment step, which aims at capturing the residual NMP quantity...

With this new recycling system from NMP, you can control your energy consumption and meet environmental requirements.

Welcome to the industry of the future!