Decarbonised hydrogen

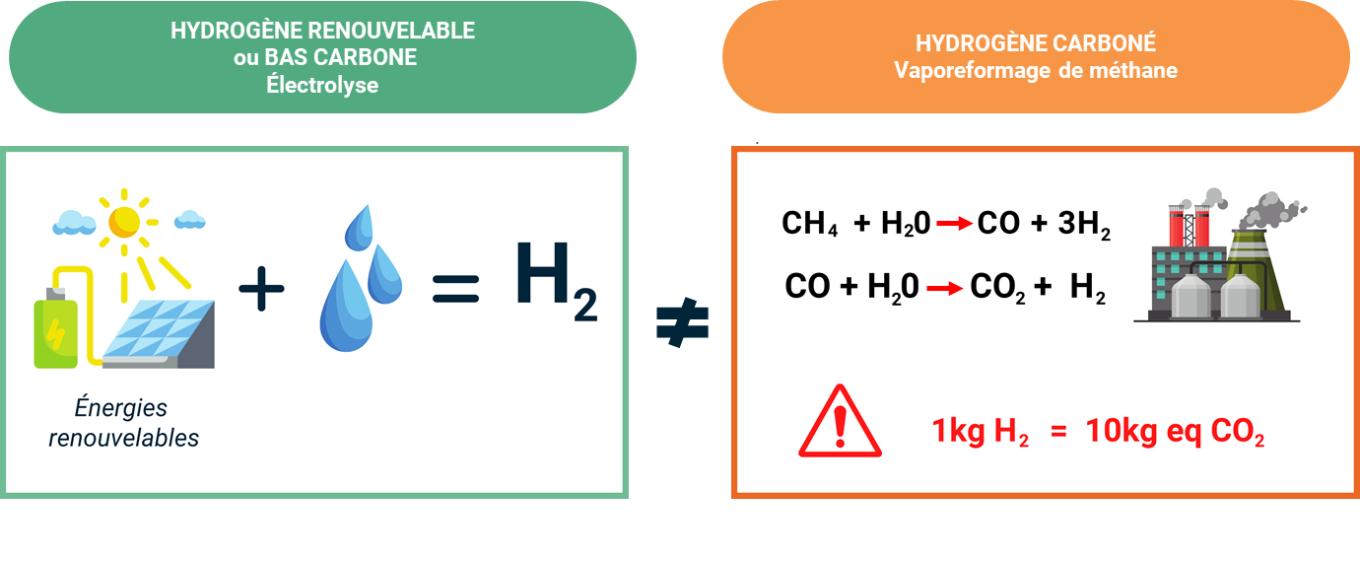

Hydrogen is an important tool in the decarbonisation of industry... provided that this hydrogen is produced in a sustainable manner.

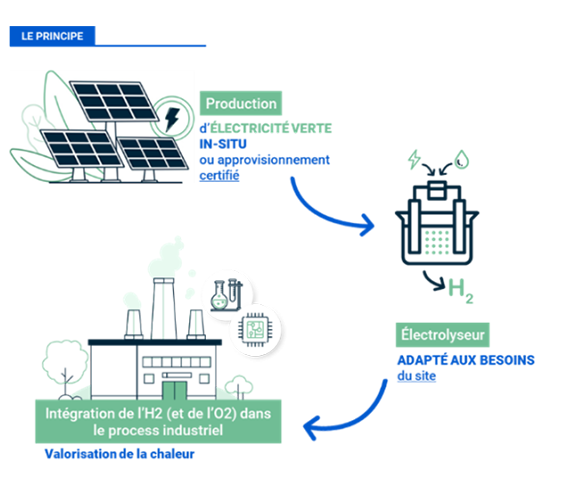

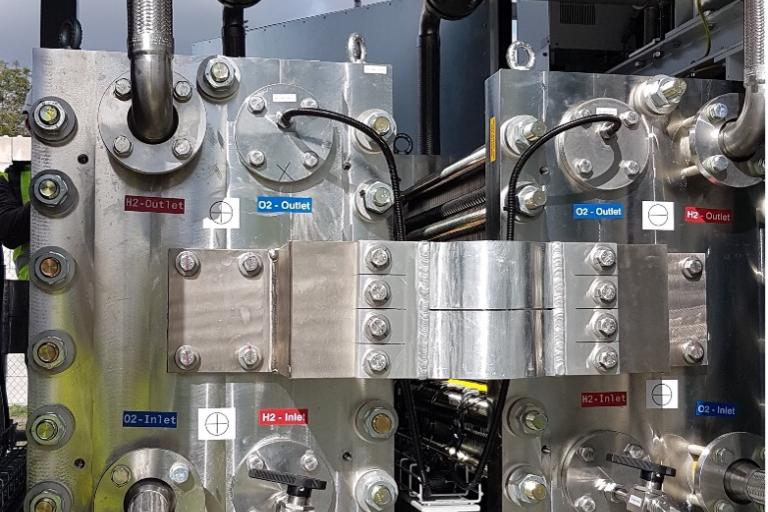

Principle of hydrogen production by water electrolysis

Hydrogen: a vector for industrial decarbonisation

Most hydrogen is produced by steam methane cracking. But this process emits a lot of greenhouse gases (GHGs): approximately 10 t of CO2 for every 1 t of H2 produced.

New technologies that emit few GHGs have matured. Electrolysis of water, in particular, can be used to produce low-carbon or renewable hydrogen and oxygen from water molecules and electricity.

EQUANS decarbonised hydrogen services for industry

Production of low power H2 for industry

Feed decarbonised H2 into your process:

- Turnkey facility for in-situ production of low power low-carbon hydrogen.

- Guaranteed H2 quality

- Securing of production

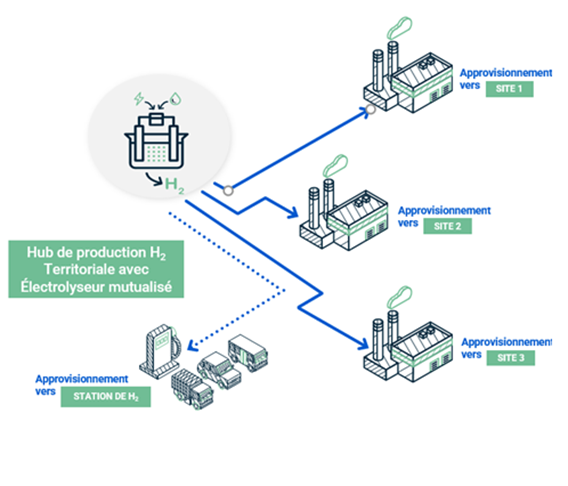

Decarbonised H2 hub

- A flagship project to unite industrial players in the same territory

- A local partnership to structure the H2 sector in the regions

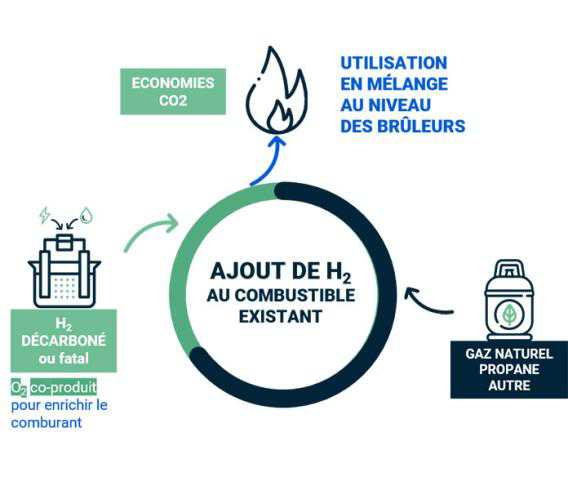

Hybrid Combustion

- A solution adapted to your process to meet your challenges

- Hybrid combustion: A major decarbonisation tool

- An expert in the integration of process gases to guide you from design to maintenance

Find out more about what we offer

They trusted us

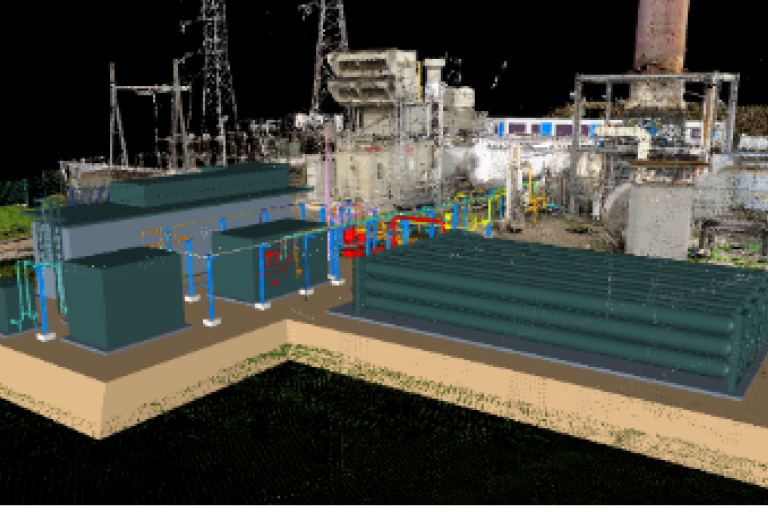

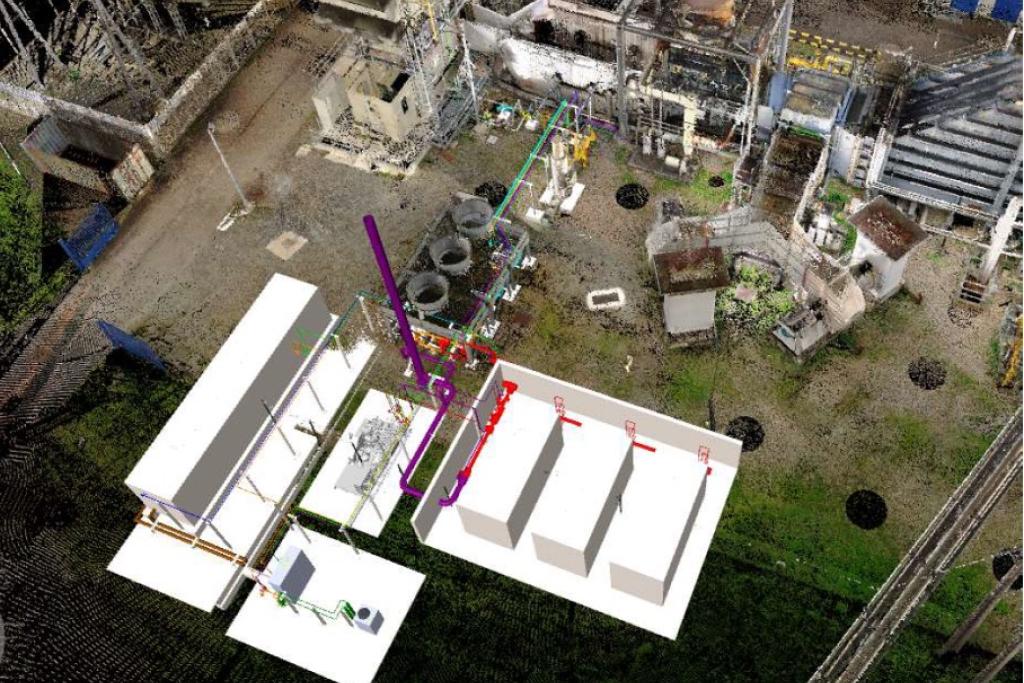

First demonstrator integrating a H2 gas turbine on the Smurfit Kappa site (Saillat-sur-Vienne 87)

ERAS ingénierie, a brand of Equans France, designs and manages the project in its entirety and is responsible for keeping to the study schedule and the technical quality of the deliverables produced:

- APS: Preliminary definition of the process

- APD : Estimation of the investment amount +/-10%.

- EPC: all trades (Piping, EIA, GC)

- Industrial risks

Axima, a brand of Equans France, carries out all the piping in compliance with the regulatory requirements related to high pressure hydrogen.