Sprinkler systems make it possible

You need the right equipment to fight a fire. Public and private places have sprinkler systems that quickly spray water onto a fire in order to contain it. These autonomous systems are currently the most reliable solutions when it comes to protecting people and property from the risk of fire. As proof of their effectiveness, 95% of fires are brought under control due to the triggering of a sprinkler. However these systems are well known for using large quantities of water. So recovering water during weekly maintenance operations can result in significant savings. Here’s how.

Sprinklers, reliable fire protection assets

Sprinkler systems make it possible to detect a fire and raise the alarm whilst containing the fire until the arrival of the emergency services. The system takes the form of a network of pipes that enable the source of a fire to be rapidly inundated with water. But how does it work in practice? When a fire breaks out, the ambient temperature rises, which activates the alarm signal and triggers the sprinkler system above the area that is on fire. The emergency services are alerted by an alarm connected to their control room.

Maintenance is crucial for fire safety

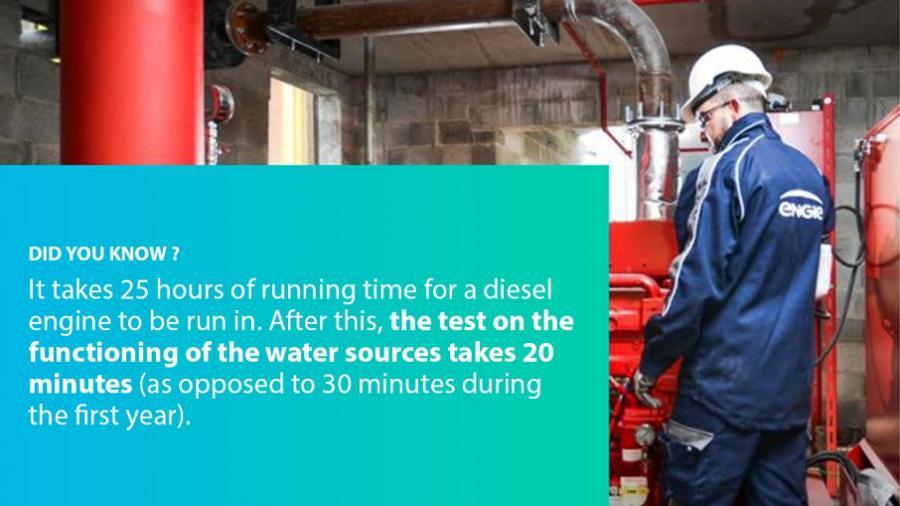

The maintenance of this equipment is subject to European legislation. Regular in-depth inspections are required to ensure its optimum performance. The APSAD R1 regulation obliges every keeper of a fire safety system to undertake weekly tests and checks on water sources, the pump motor set and the control rooms. Diesel engines must be water-cooled if they are to function correctly. In a standard system, the cooling water is discharged directly to waste.

Whilst the tests are vital to the proper functioning of the sprinkler system, they result in high water consumption. However, it is possible to reduce the amount of water that goes to waste during weekly checks and when sprinklers are in operation.

Recovering water used to cool sprinkler systems

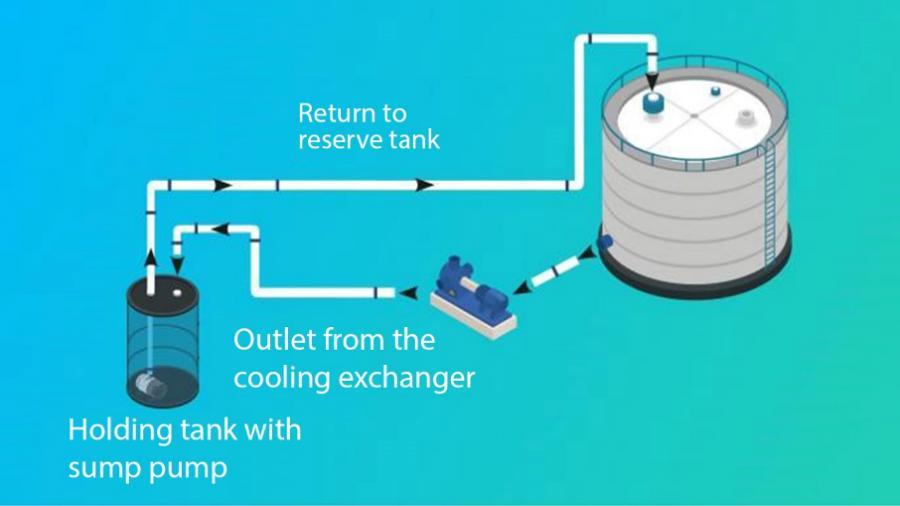

The average volume of water required to cool the motor of a sprinkler system varies between 120 m³ and 300 m³ per year. This volume depends on the size of motors, their cooling systems and the duration of weekly tests. A substantial sum of money can be saved by recovering and reusing the water used to cool the motors during the weekly tests. To achieve this, EQUANS France recommends that its clients install an autonomous closed circuit recovery and reinjection system incorporating a water storage tank.

It should be noted that recycling water used for cooling diesel motors is accepted by the CNPP* (and in Article 12.4.1 of the APSAD R1 regulation).

The very raison d’etre of EQUANS

The very raison d’etre of EQUANS France is to support our clients in their zero carbon transition. This water recovery system does precisely that, enabling savings, limiting environmental impact and providing protection to buildings and their occupants.