TINEA Industrial Automation

Industrial automation is central to many company’s concerns.

EQUANS Digital Solutions guides industrial sites wanting to improve their economic and environmental performance. Our experts design tailored solutions to optimise the production, security and compliance of sites.

Automation & Information Systems

Solutions for the industry of the future

Our offer

AUTOMATION & INFORMATION SYSTEMS

Industrial PLCs, supervision of automated processes and IT

Partner of the digital factory

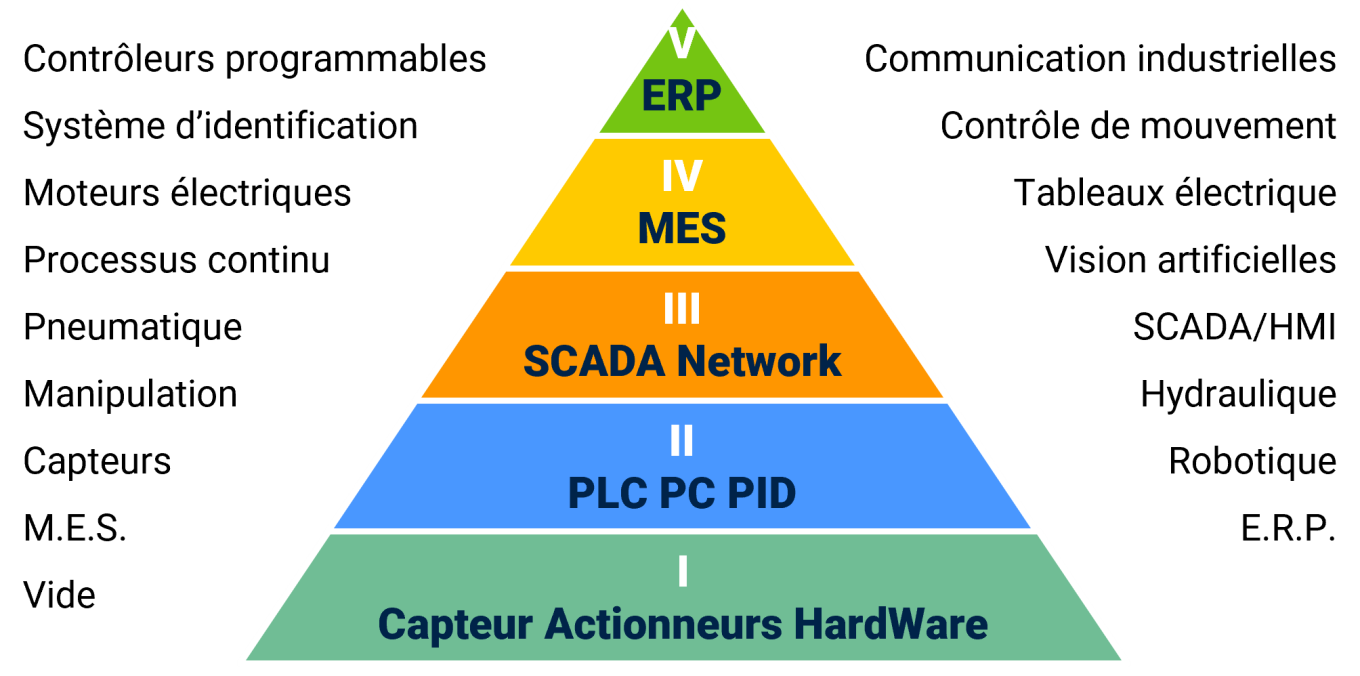

We guide our customers throughout the value chain of the MES, from field equipment to ERP.

-

AUDITS, ADVICE AND EXPERTISE

AUDITS, ADVICE AND EXPERTISE

- Change design studies

- Complete diagnosis, advice

- Analysis of strategic issues

- Drafting of specifications

- Purchase of equipment and software

- Project management -

DESIGN, INTEGRATION AND DEVELOPMENT, MES MODULES

DESIGN, INTEGRATION AND DEVELOPMENT, MES MODULES

- IT supervision automation

- Process availability and security

- Reverse engineering

- Integration of multi-technical systems/solutions

- Interoperability of heterogeneous systems

- IS system design, IT/OT convergence, Cyber security rules

- Technical support, testing, simulation, interfacing -

SERVICES, GLOBAL MAINTENANCE

SERVICES, GLOBAL MAINTENANCE

- Long-term support contract

- Hardware and software operational maintenance

- Preparation of maintenance contracts with progress clauses

- Telephone support and troubleshooting

- Remote maintenance, On-site servicing

- Training in use of tools

Challenges of the digital factory

-

Objectives of the MES

Objectives of the MES

- System subject to Industrial Strategies

- Coordination of manufacturing operations

- Digitalise, acquire, process and share information, standardise and circulate best practice

- Simulation of the production system, transmit, train and anticipate

- Interoperable / Secure exchange / Integrity of data between ISs / Availability analysis tools, OEE, KPIs, etc. -

functional advantages

functional advantages

- Process manufacturing and work orders fluidly, ongoing optimisation of manufacturing process times

- Visualise sequencing of operations, instructions and events

- Control quality in a closed loop and at every stage

- Increase efficiency and life cycles, optimise manufacturing flexibility and maintenance costs

- Traceability, genealogy of finished and semi-finished products

- Analyse the operation and performance of equipment and team members -

industrial profits

industrial profits

- Increase net result in line with industrial strategies

- Efficiency, adaptation, quick decision-making, zero paper, real-time information, limitation of controls

- Boosted performance, improved agility and anticipation, long-term optimisation of the service life of equipment, overall rate of return, OEE, work-in-progress, work flows

- Improved quality, limitation of compliance costs, losses

- Operator, consumer and ecosystem security

- Circulation of common procedures, feedback of information (Workflow)