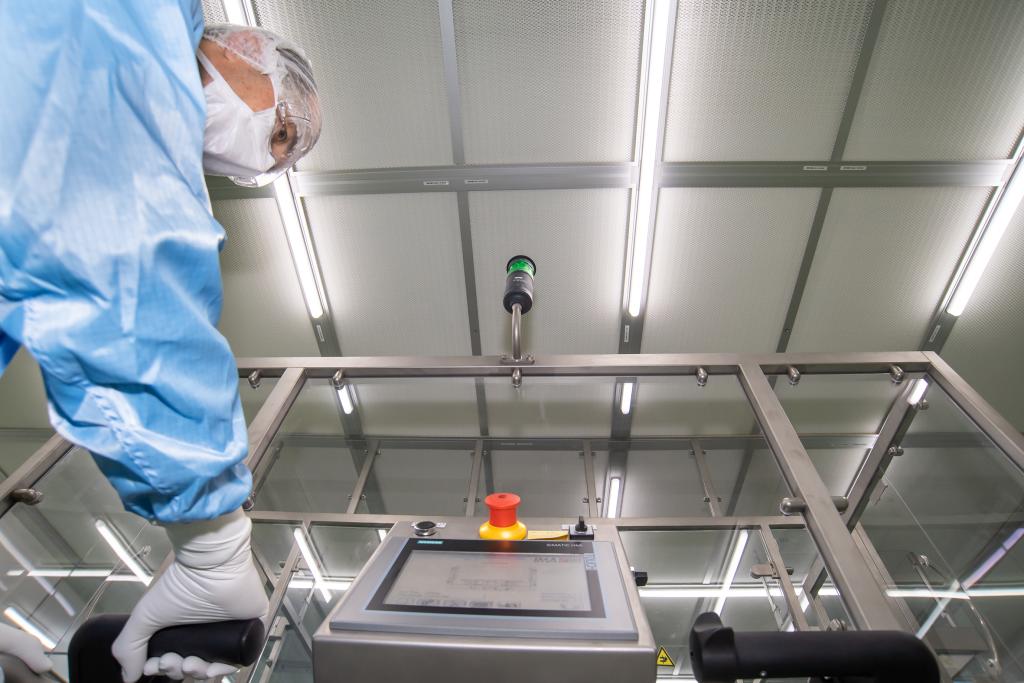

Clean room, an optimised space for your production

A clean room is a room with a controlled atmosphere, specially designed for certain business sectors (food industry, aerospace, pharmaceuticals, etc.) to protect people and the products handled from potential contamination or interactions with non-purified air.

Equans France has specialised in the creation of clean rooms for over 30 years. Here we explain how these special rooms work.

What is a clean room?

A clean room is an enclosed space in which several environmental criteria are controlled: concentration of particles suspended in the air, humidity, temperature, gas emissions, etc. Variations in these different criteria can damage the equipment being handled, contaminate food or pharmaceutical products and encourage the circulation of potentially hazardous elements, such as viruses or explosive particles.

Apart from operating theatres, clean rooms are mainly constructed in health care establishments, in the food industry, in microelectronics, pharmaceuticals, cosmetics and biotechnologies, as well as in the space sector.

They have to comply with standard ISO 14644-1, which specifies the classification of the particular cleanliness of the air in terms of concentration of particles suspended in the air.

This classification guarantees the protection and security of the people working in the clean rooms, as well as the cleanliness and non-contamination of the products handled (cosmetics, food, medical equipment).

Equans France, designer of clean rooms for 30 years

Clean room design depends on the business sector and the criteria to be measured (dust levels, temperature, light, etc.). Equans France, an expert in the design of clean rooms for 30 years, studies and creates clean rooms that meet strict hygiene and security criteria.

From study to design, from commissioning to maintenance, Equans France operates at every level to produce clean rooms that meet the hygiene and security requirements of establishments, in accordance with sanitary standards and regulations.

For over 30 years, Equans France has supported you in the implementation of its expertise to protect personnel, avoid environmental contamination and prevent damage to products.

Our presentation video

Our expertise in a variety of fields

Pharmaceutical / Laboratories

Laboratories handle infectious agents that can be highly pathogenic. To guarantee a safe work space for researchers and avoid any risk of contamination, research areas must be designed in sterile, regularly inspected environments.

Sartorius Stedim

International manufacturer of pharmaceutical and laboratory equipment. Construct two new clean rooms within a tight deadline, as well as two laboratories:

- Creation of two ISO7 clean rooms 300 and 1,500 m² and two analysis laboratories

- Redevelopment of two warehouses 12,000 and 4,000 m²

- Detailed design and execution study, performance of works in all trades (civil engineering, carpentry, clean concept, HVAC, AC production, fire safety, low/high current), air handling in the clean room via four 61,000 m³/h recyclers.

Food industry

In the food industry, the hygiene and cleanliness rules must meet strict standards, in order to avoid contamination of food by bacteria, and protect the quality of food and/or beverages.

Orangina Scwheppes

Cooling and air handling to sanitise the atmosphere of bottling plants:

- Aseptic air handling for a new bottling room:

- ISO 8

- Flow rate: 40,000 m3/h

- Cooling:

- Additional energy study for improved capacity

- Positive cooling for workshops

Microelectronics

To avoid electronic components being damaged by moisture, clean rooms constructed for the microelectronics sector must be able to measure and manage humidity and particles in the air.

Soitec Corsica

Renovation and 600 m² extension:

- Turnkey support for all trades for the redevelopment of an existing clean room in the ISO4 production phase without interruption for the installation of a new production line.

Cosmetics

The cosmetics industry, similar to the food industry and pharmaceuticals in terms of hygiene and security, must ensure that no elements infect or alter the quality of the product.

L'Oréal

Performance of studies and works relating to the reconditioning of the HVAC system of three clean rooms in line with standard ISO 14644-1 (ISO 8):

- Predefinition and design studies: air diffusion, installation of air handling units, cold production for the three workshops

- Works: installation and commissioning of the hydraulic (chilled water) and ventilation systems, the air conditioning and heating systems, and the air handling units.

Space & Aeronautics

Clean rooms in the Aerospace sector are very large and have the most demanding requirements. Their design must enable the construction of partitions and a high-performance HVAC system.

Thales Alenia Space

Delivery of the turnkey building:

- two 480 m² ISO 5 rooms, with height 10.5 m, including two 180 m² fan walls

- one 230 m² ISO 8 room, with height 12 m

- more than 390,000 m³/h of air treated

- more than 4,000 m² of clean room partitions

constructed in less than 6 months.

Batteries

The manufacture of electric batteries calls for high-performance work spaces that comply with strict sanitary and security standards.

GigaFactory en Suède

The design, supply and installation of technological equipment for the creation of a Li-ion battery production unit in Sweden encompasses:

- Design and creation of an ISO 6 48,000 m² anhydrous room (dew point -40)

- Electrolyte storage and distribution

- Utility management (heating water, ice, process water, compressed air)