15.09.2022

Energy Sobriety: What if we recovered the heat to cool the planet?

How to reconcile the significant refrigeration and heating needs of strategic industries such as food processing or chemicals with increasingly strong energy constraints? How can we optimize refrigeration or heat production facilities that are particularly energy-hungry?

The decarbonization of industry, but also of heating networks, is an urgent challenge to be met at a time when calls for energy sobriety are multiplying in view of the winter period. Between optimization, performance of fluids and recovery of waste heat, innovations around heat pumps make them one of the keys to the future.

The environmental and economic advantages are numerous while meeting regulatory requirements. The implementation of these innovative solutions benefits from a favorable context due to French and European subsidies within the framework of investment and recovery plans.

Heat pump and industry

Industrial processes require energy, heat and/or cold. Some productions require alternating hot and cold simultaneously. This is notably the case for the food industry - in particular dairy products, meat processing, fruit and vegetables, malting plants, beverages and canning plants - fine chemistry and pharmaceuticals with synthesis cycles or even for the paper industry.

The food industry is known for avoiding any form of waste, especially of raw material. Given the current tension on the energy markets, this is becoming a determining factor not only because of the significant increase in costs, but also because of the threats to supply and the risks of gas cuts in the coming months.

The principle of the cooling units installed on industrial processes is to evacuate heat. This is what allows a component or food to be treated or to lower and stabilize the temperature of a cold room. The evacuated heat is most often lost as in the common systems of air-conditioning which propel cold air in a room while evacuating the calories.

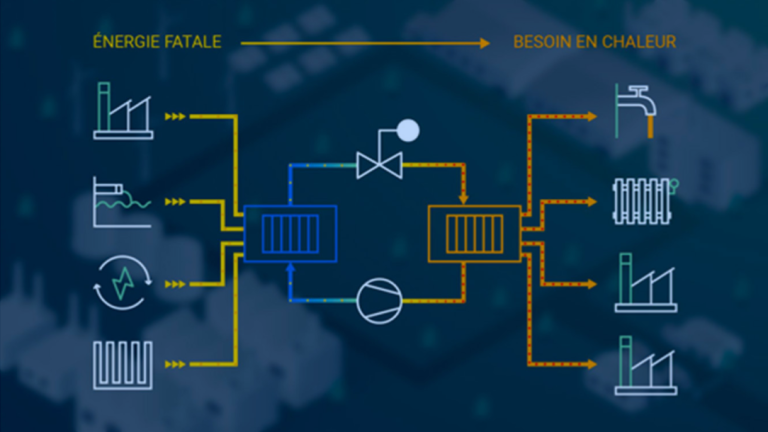

The principle of the heat pump is to recover this heat from the refrigeration systems, raise its temperature so that it can be reused in another part of the industrial process. The use of a heat pump makes it possible to valorize waste heat for industrial processes but also for heat networks.

The objective is to protect against rising energy prices while reducing greenhouse gas emissions and ensuring independence from fossil fuels.

Operation of the heat pump

The heat pump operates in a closed circuit, containing a refrigerant that evaporates and condenses depending on the pressure and temperature of the circuit. To generate heat, the refrigerant absorbs waste energy from industrial processes and refrigeration systems. The fluid is then vaporized and compressed, increasing its temperature. The heat from the vaporized fluid is captured by an exchanger, allowing water to be heated up to 120 degrees, increasing the usability throughout the process.

While energy autonomy and independence are major concerns for manufacturers, the heat pump does not require fossil fuel. It is also three times more efficient than com- bustion with coefficients of performance between 3 and 4.

Indeed, it uses a free raw material: waste heat. In addition, its various components consume little energy. The result is reduced, optimized consumption, with no waste and a decarbonized electricity supply that is much less exposed to disruptions than gas.

In addition, thanks to support mechanisms given its environmental benefits, the return on investment is less than two years, which reinforces the attractiveness of this technology among manufacturers.

Perspectives and challenges

The heat pump can not only substitute for fossil fuel but also recover waste heat and reclaim it by feeding it back into the manufacturing process.

In France, the energy used in industry represents 426 TWh according to the data of the ADEME (Agency for the Environment and Energy Management). Applications below 120° using fossil energy represent a quarter of this energy expenditure. The food, pharmaceutical and fine chemical industries represent 30% of the uses. The recovery of waste heat from refrigeration and cold air compression systems is estimated at 34 TWh.

Thus, the potential use of heat pumps in industry can be estimated at 130 TWh, or more than a third of the energy used today.

The international context and the economic situation are pushing many players to integrate heat pumps into their industrial processes. But it is essential to rely on expertise to determine where to reinject this heat and retain the benefits and virtues of the technology.

At RichesMonts, the results are there!

Axima Réfrigération's teams worked with the Compagnie des Fromages & RichesMonts (CF&R) which manufactures the famous camemberts, coulommiers, bries and raclette cheeses. Following an energy audit in 2015, the company decided to improve its energy performance. A heat pump was installed with a thermo-frigopump to recover waste heat and use it in the production cycle. Indeed, the production of soft cheeses requires a large quantity of cold, the production of which implied the discharge of water at 50°C. However, the industrial process also required large quantities of hot water at over 80°C to ensure the pasteurization of the milk.

The installation of a heat pump was carefully monitored to assess the benefits. The results are there: nearly 4,300 MWh of waste heat recovered in the first year and a prospect of 5,700 MWh synonymous with a 23% reduction in gas consumption, or more than 1,000 t of CO2 avoided each year.

A technology adapted to heating networks

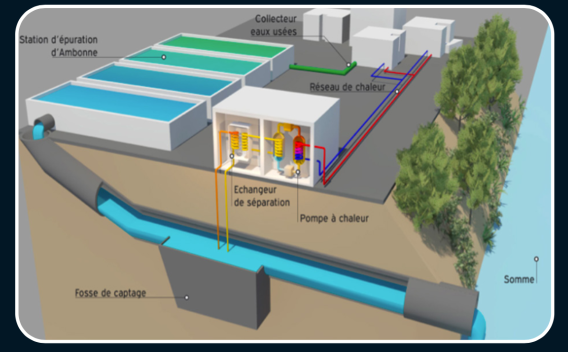

To supply its heating network, Amiens has set up a heat pump to recover the calories present in the water of a wastewater treatment plant. It is thanks to an exchanger that it recovers the thermal energy, which is then reinjected into the Amiens Énergies network.

Axima refrigeration

Expert in cooling units and climatic engineering, Axima Réfrigération is an entity of Equans France, world leader in multi-technical services, and benefits from more than 15 years of experience in the use of heat pumps for industry.

Axima Réfrigération's experts have a perfect mastery of the technology and are able to integrate it in a personalized way to each industrial process. This implies measuring and targeting the heat recovery to optimize its use by identifying the existing deposits and needs beforehand.

As close as possible to the field, our teams receive ongoing training to assist them in obtaining financing and subsidies thanks to their in-depth knowledge of the regulations.